A new generation of chairside dental 3D printing systems demonstrated in Dubai is capable of producing ceramic dental crowns in roughly 10 minutes of print time, marking a significant shift toward same-visit dental restorations.

However, the full clinical process usually still takes longer because scanning, preparation, finishing, and fitting remain necessary steps.

Even so, this technology moves dentistry closer to fully digital, single-appointment tooth restoration.

Table of Contents

ToggleWhat Actually Debuted in Dubai

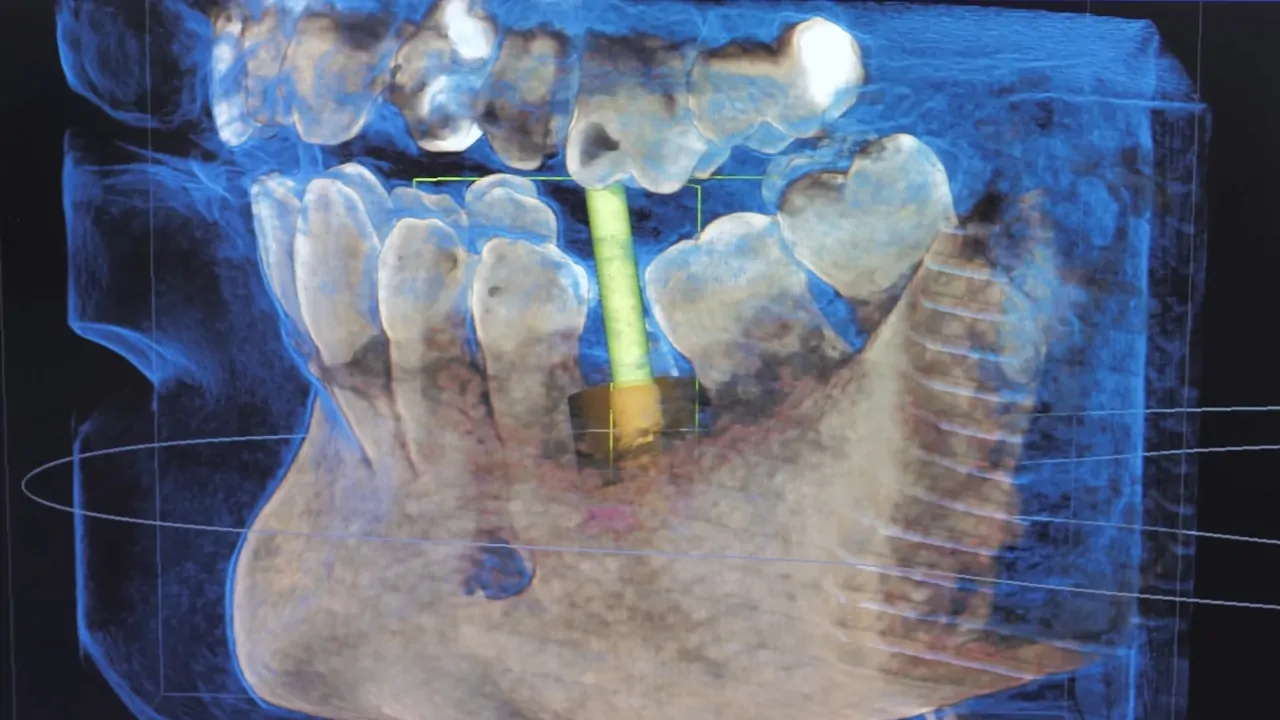

At the AEEDC Dubai dental technology exhibition in 2026, several manufacturers showcased integrated chairside systems designed specifically for rapid crown fabrication. One of the most discussed innovations included compact printers capable of producing ceramic crowns in about ten minutes using specialized resin vats optimized for dental ceramics.

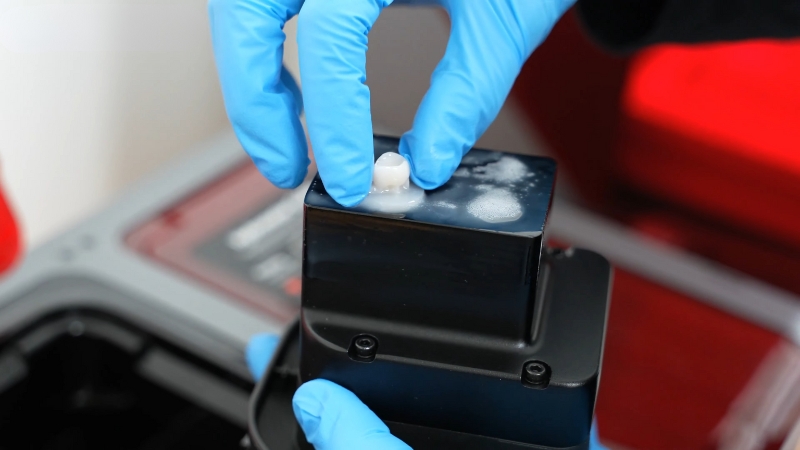

These printers combine multiple functions that previously required separate equipment. Some units integrate printing, curing, and finishing workflows into portable, clinic-friendly devices designed for smaller dental offices.

Another system highlighted at the event uses AI-assisted design combined with ceramic-dominant resins containing more than 60 percent ceramic filler. This produces restorations designed to closely mimic natural enamel translucency while maintaining strength.

The result is not just faster crowns but a broader shift toward digital dentistry where scanning, design, fabrication, and placement occur in one clinical visit.

How Chairside Crown Printing Works in Practice

The workflow is fundamentally different from traditional crown fabrication.

First, dentists capture a digital 3D scan of the patient’s tooth instead of using traditional impression materials. Digital impressions are faster and often more comfortable for patients.

Next, specialized software automatically proposes crown shapes using anatomical databases and AI modeling tools. Dentists adjust the design chairside before sending it directly to the printer.

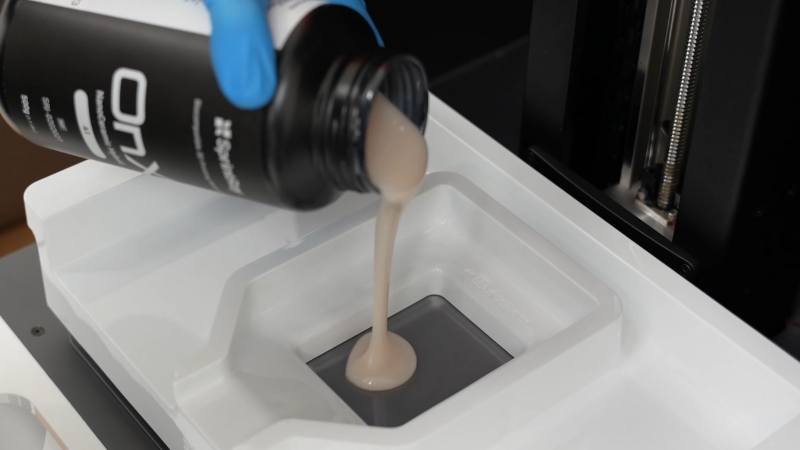

Printing then begins using ceramic-enhanced resins. Some systems claim print times as short as ten minutes, although final curing, polishing, and fitting add additional time before placement.

Even with these extra steps, modern same-day crown procedures usually take between one and two hours, still dramatically faster than traditional multi-visit treatments.

Comparison: Traditional Crowns vs Chairside Printed Crowns

Factor

Traditional crowns

Chairside 3D-printed crowns

Visits required

Usually two

Often one

Fabrication time

Days to weeks

Minutes to hours

Temporary crown needed

Usually yes

Often not

Patient comfort

Impression trays

Digital scanning

Production location

External lab

Dental clinic

Traditional crowns typically involve temporary restorations while labs fabricate permanent ones, sometimes over several weeks.

Chairside printing compresses that timeline dramatically.

While crowns repair damaged teeth, other restorative options remain important depending on the patient’s condition. For example, removable prosthetics like dentures are still widely used when multiple teeth are missing or when full-arch restoration is required.

The emerging trend is digital integration across all restoration types. The same scanning and design tools used for crowns are increasingly being adapted for bridges, implants, aligners, surgical guides, and full prosthetic workflows. Dentistry is gradually becoming a digitally driven field rather than a lab-dependent craft.

Material Science Is Driving the Speed

One of the biggest breakthroughs enabling rapid crown printing is material chemistry.

Modern dental printing resins combine:

Researchers are also working on printing zirconia crowns directly. New experimental processes have reduced sintering steps from tens of hours to potentially same-day production, which could further accelerate adoption once commercialized.

This material evolution is what makes ten-minute printing technically possible.

Clinical Benefits Dentists Are Highlighting

Faster Treatment Cycles

Same-day crowns eliminate waiting periods and reduce the need for temporary restorations.

Greater Precision

Digital design allows extremely accurate fits, reducing adjustment time.

Better Patient Experience

Digital impressions replace messy molds, and fewer visits mean less disruption to daily life.

Potential Long-Term Cost Efficiency

Although equipment investment is high, eliminating lab fees and reducing chair time can offset costs over time.

Limitations and Realistic Expectations

Despite promising demonstrations, several factors still limit universal adoption.

Complex dental cases may require additional treatment before crown placement. Some patients still need traditional lab fabrication depending on tooth position, bite forces, or material choice. Total procedure time usually remains closer to one to two hours rather than ten minutes.

There is also a learning curve for dentists transitioning from conventional methods to digital workflows.

Why This Matters Beyond Dentistry

Chairside 3D printing reflects a broader trend in healthcare: moving production directly into clinics. Similar shifts are happening in orthopedics, hearing aids, prosthetics, and surgical planning.

Localized production means:

Dentistry happens to be one of the fastest-moving sectors because dental restorations are highly individualized and already heavily digitized.

The Future Direction

Based on current industry momentum, several developments are likely over the next few years:

As these technologies mature, same-day dental restoration may shift from a premium option to a standard practice.

Bottom Line

@idigitaldentistry The Truth About 3D Printed Crowns “I don’t see many people that I consider serious putting finals in.” That’s Rune Fisker from 3Shape getting brutally honest about printed crowns in 2026. SprintRay’s Midas has generated massive hype. Crowds at ADF Paris. Espresso machine concept. Drop in a capsule, crown comes out. But here’s what nobody’s talking about: the cost per crown is $20 vs $2 for traditional printing. And the CEO of Ivoclar says ceramic crowns will ALWAYS have superior material properties to resin. Temps? Absolutely. Dentists are printing temps big time. Finals? Not yet. 70% of printer usage is models. 10% guides. 10% splints. The rest is temps and everything else. Meanwhile, people in Ukraine and Romania are placing printed finals every day. But in the western mass market? Minimal adoption among serious practitioners. The aesthetics have improved dramatically. Crown HT is way better than first-gen opaque resins. But material longevity? Still questionable. Remember first-generation full zirconia? Dentists called it “a snowball in the mouth.” Look where we are now. As Justin from Asiga says: “We’re only one innovation away.” But we’re not there yet. #DigitalDentistry #3DPrinting #DentalCrowns #SprintRay #PrintedCrowns #DentalTechnology #3Shape #RuneFisker #DentalInnovation #CADCAMDentistry #DentalMaterials #ModernDentistry #DentalDebate #PrintedRestoration #DentalTruth #ResinCrowns #DentistryFacts ♬ original sound – Institute of Digital Dentistry

Chairside 3D printing capable of producing ceramic crowns in roughly ten minutes is real and already being demonstrated publicly, including at major dental technology events in Dubai.

While the total clinical procedure still takes longer, the shift toward single-visit restorations is accelerating. Dentistry is moving rapidly toward a fully digital workflow where scanning, design, fabrication, and placement happen in one appointment, improving efficiency for dentists and convenience for patients.

Related Posts:

- Why You Should Consider Veneers in Dubai for Your…

- US Health Insurance System Is Driving Americans to the Brink

- Map of New York City, New York – Geography,…

- New Sentara Wellness Center Aims to Enhance Community Health

- New Hampshire Population in 2025 - Latest…

- Map of State of New York - Cities, Geography,…